Features

EJOY poultry manure dryer has been designed for use in tropical climate.

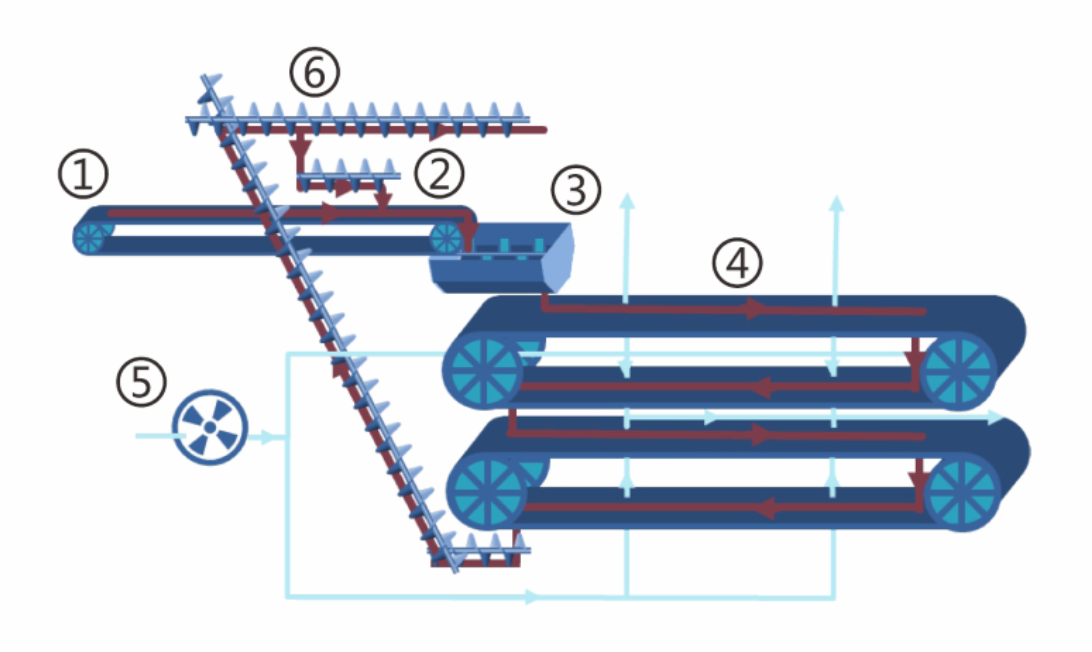

The goal of drier is to turn poultry manure into a more valuable product. Manure will be dried to a dry matter content of 20% moisture. Poultry manure can be dried using hot air. Outside air or farmhouse air can be used during the dry period. During the wet mon-soon, outside air or farmhouse air are not enough and the air need to be heated by using external heat sources.

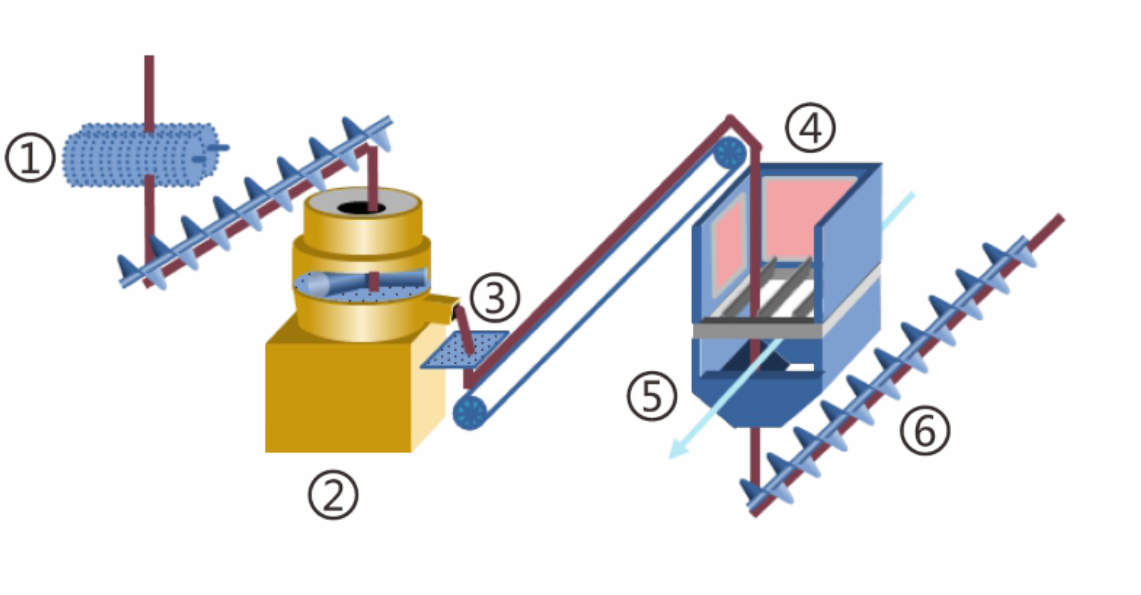

EJOY provides a complete set system with all equipment to have pellets produced from sludge on a semi-automated procedure. Pelletizing greatly reduce volume and thus reduce transport and storage cost. The pelletizing plant also provides new marketing opportunities to sell the product. The dried product with 15% moisture is stored in a bunker. Then the material is minimized in a crusher after which a mixing screw conveyor (frequency controlled) transfers the material onward to the press. If the material is dry, steam can be added here. Further the pellet is cooled and hardened in the cooler by drying with air. Dust is removed from the air by a cyclone.

The pelletizing plant consists of the following parts:

Crusher and augers

Screw conveyor

Pellet press

Cooler with duct removal by cyclone

Special sieve for the removing fine dust

Dried chicken manure

Dried chicken manure VS particles