Chicken Floor Breeding System

Automatic broiler pan feeding equipment

● Suitable for broilers requirement during any growing period

● This feeding system deliver feed through auger, including main feed line and feed line.

● Main feed line: deliver feed from silo to the hopper in the poultry house. There is one feed sensor at the end of main feed line, which can control drive motor on and off to realize automatic delivery feed.

● Feed line: This system can deliver feed automatically by feed sensor at the end of feed line to control drive motor on-off.

● Main feed line system composing

- Added: 2021-08-24

- Views: 5173

- Features

- Advantage

- Detailed introduction

Features

AUTOMATIC BROILER FEEDING SYSTEM(POULTRY EQUIPMENT)

SUITABLE FOR BROILERS REQUIREMENT DURING ANY GROWING PERIOD

This feeding system deliver feed through auger, including main feed line and feed line.It is important part of poultry equipment.

●Main feed line: deliver feed from silo to the hopper in the poultry house. There is one feed sensor at the end of main feed line, which can control drive motor on and off to realize automatic delivery feed.

●Advantage: Reduce labour intensity. One person is enough for one house.

●Feed line: This system can deliver feed automatically by feed sensor at the end of feed line to control drive motor on-off

Broiler feed pan

●Typical 05 feed pan has 6 feed level, can be manual and automatic adjusted. Other two feed pans have 13 level to adjust.

●Slide shutter-off can adjust feed amount from complete open to complete close.

●Adjusting the feeding amount of typical 05 pan convenient, fast and accurate.After pan is assembled,to hold its grill, rotate up and down and fix position when regulating.

●Pan plate can be disassembled on the ground working as specialy pan for 0-7 day old chicken.

●V-pan plate design can reduce feed storage at pan bottom. Bird can have fresh feed every day. This design can also prevent bird from staying on the plate too long.

●Edge of pan plate tilt towards the center which can avoid the waste of feed.

●Smooth edge can prevent the bird craw from hurt and make sure safety and comfort feeding.

●Assemble type of the pan in the pipe can be fixed or swing.

Drive Motor and Delivery System

Drive Motor(Tai Wan product,with overloading protection,IP54)

Power:0.75 Kw

VOLTAGE:380 v

HZ:50Hz 3-PHASE

Delivery System

Feed Pipe: 4 holes/3m

Diameter:φ45 mm

250g/m2 Material :galvanized steel,zinc 250g/m2

Thickness :1.2 mm

Auger: Top rank quality origin in South Africa

Delivery capacity :450 Kg/h

Hopper

Capacity :115 L

Material :galvanized steel

Thickness :1.0mm

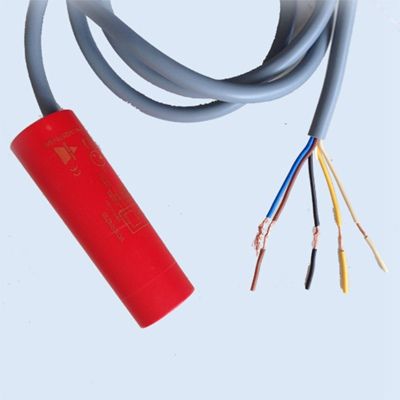

Feed Sensor

a. Feed sensor can be installed in the feed pan (NO), when there is lack of feed, motor will start and deliver feed; when there is full of feed, motor will stop (used for feed line and main feed line).

b. Feed sensor can be installed at the bottom of hopper(NC), function is just opposite with (NO ).

Hang system of feed Line

●Hang System of Feed line is composed of winch, pulley, fixed material, steel wire and wire clamp and so on.

●Height of feed line system can be adjusted by winch, appropriate pan height is very important for poultry growing.

Correct Height: Bird Back height= Height of Upper and outer edge of pan grill

●Feed line can be lifted by hang system, which significantly improve cleaning work and offer convenience for birds moving in and out.It also be design according to other automatic poultry equipment.

Advantage

● Advantage: Automatic poultry equipment reduce labour intensity. One person is enough for one house.

● Multi-level protection with protecting barrier, safety and reliability.

● Sturdy connected between feeding pipe, well sealed.

● High quality Double-sided galvanized sheet, more than 10 years life.