Parameter

Pig Farm Intelligent Feeding System

Control the feed quantity accurately according to each sow.

The optimal feeding curve setting.Feed automatically and accurately in real-tine.Save labor effectively.

Intelligent Feeding System improves feeding efficiently and financially.

Remote control with IOT platform.

1. NF01 Feeder For Farrowing Phase Sow

Main Technical Parameters

• Power: DC24V;

• Rated power: <20W;

• Control output: auger/water control

• Collection input: water intake and feed intake

• Accuracy of laying-off : particles 3% and powder 1%

Main Functions

• Two feeding states: predelivery/lactation, and automatic switching of centralized labor;

• To achieve the optimal feeding effect, set different feeding times, feeding proportion and water and

feed ratio every day;

• Set feed amount accurately as per individual differences, such as birth parity, litter size, backfat value

etc.;

• Interacted Feeding, no laying-off until twiddle is detected. 24 hours laying-off

• Automatically add or reduce meal times as per different situations;

• Analyze data with big data platform to form automatically feed control model

• One-click bind sows’ ear tags with materials data to switch feeding state;

• Proper water/feed ration provides perfect palatability, and makes fast weight gain and high survival

rate;

• Intelligent adjustment, no manual intervention, optimize labor, reduce cost and increase efficiency;

2. NF02 Feeder For Gestation Phase Sow

Main Technical Parameters

• Power: DC24V;

• Rated power: <20W;

• Control output: auger control

• Accuracy of laying-off : particles 3% and powder 1%

Main Functions

• To achieve the optimal feeding effect, set different feeding times, feeding proportion

and water and feed ratio every day;

• Feeding curves can be set for primiparity and multiparity. Automatically switch feeding

curves as per parity to adjust feeding amount ;

• Accurately control fatness. Bases on day-age automatically adjust reference backfat

value to calculate needed feed amount;

• One-click bind sows’ ear tags with materials data to switch feeding state;

• Automatically add or reduce meal times as per different situations;

• Intelligent adjustment, no manual intervention, optimize labor, reduce cost and increase

efficiency;

• Dynamic data management of intake and herds to provide guidance for feeding

decision

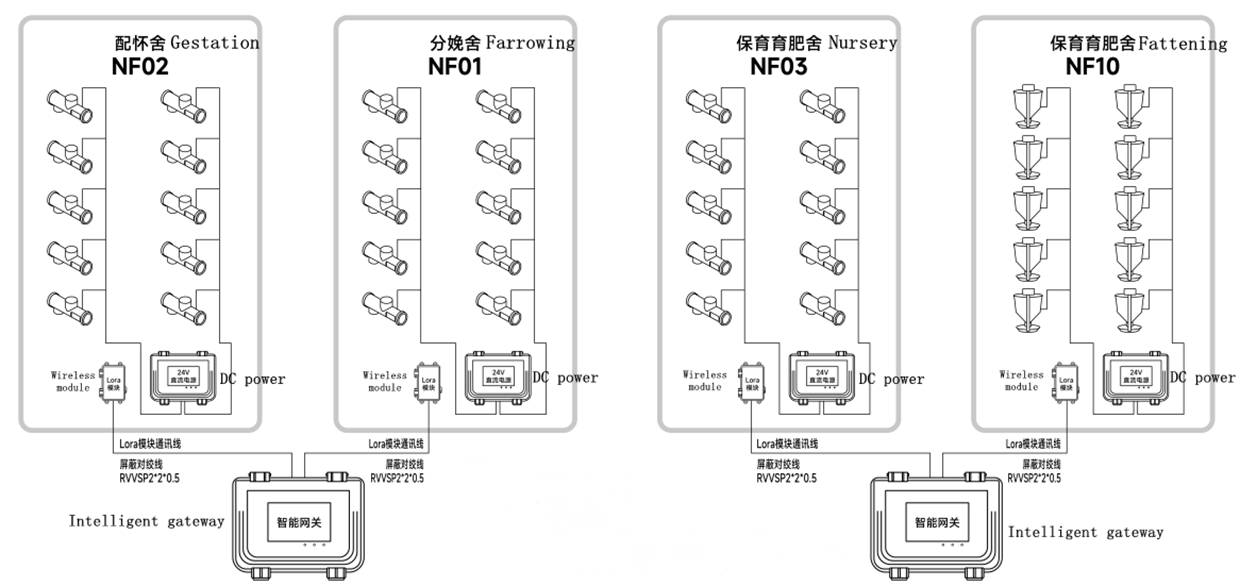

3. Intelligent Gateway G1

Main Functions

• Support Max. 600 sets of NF01 or NF02.

• Act as controller of the feeders,Can be connected to the IoT platform through network cables or 4G modules

• Power supply: AC85-305V, 50/60Hz.

4. Lora Wireless Module

Main Functions

• Wireless module to make data communications with the feeders

• Support 120 sets of feeders NF01 or NF02 within one room.

5. DC Power Source

Main Functions

• Wireless module to make data communications with the feeders

• Support 120 sets of feeders NF01 or NF02 within one room.

6. Remote control with IOT platform

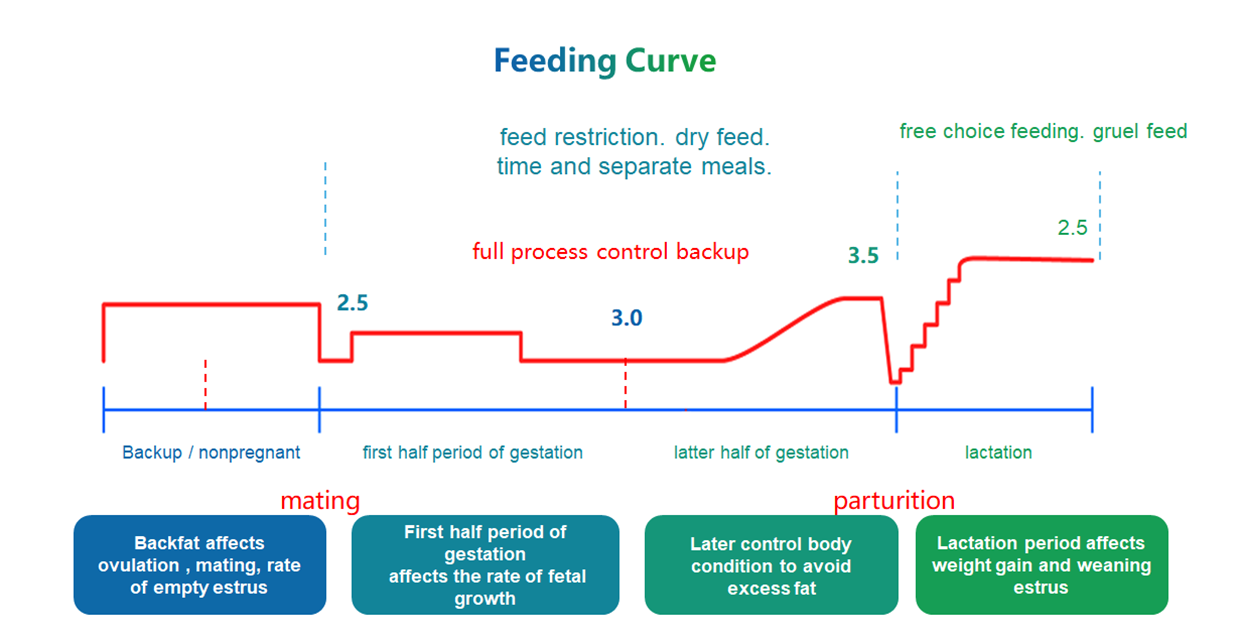

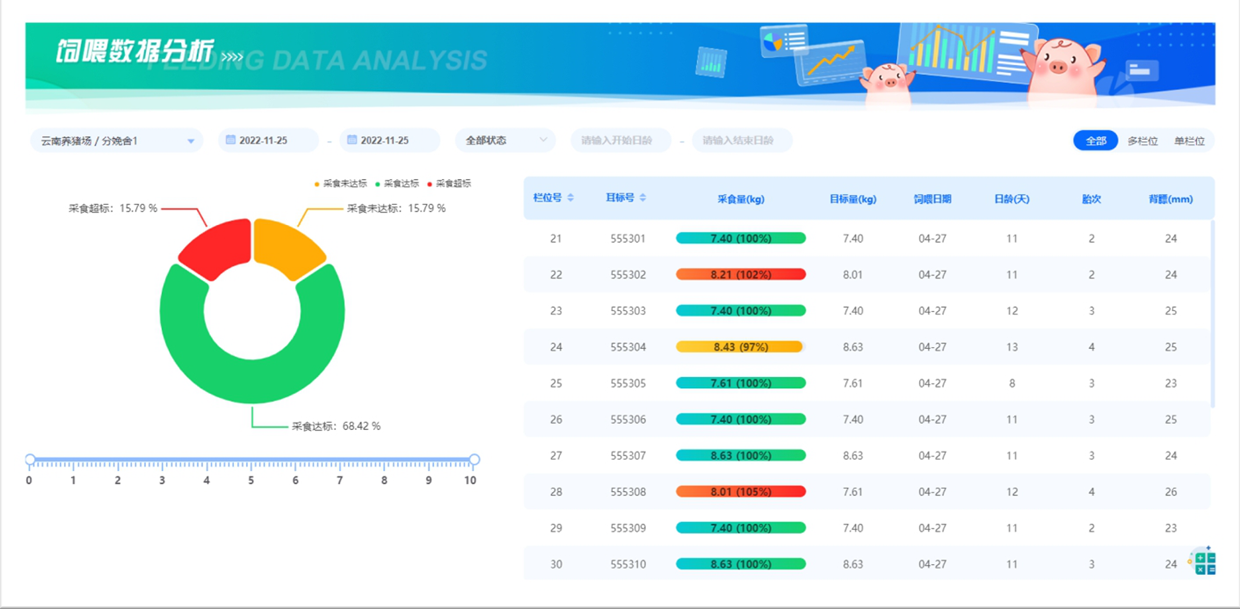

The optimal dietary effect was achieved by setting different meals and feeding proportion every day.

Feeding curves can be set at first birth and after birth. Feeding curves can be automatically switched according to the parity to adjust feeding quantity.

Accurate fattening control, the system automatically adjusts the reference backfat value of pregnant sows in each period according to the day age, and adjusts the feeding amount according to the current actual backfat calculation.

Associate material files, bind sow ear tags with one key, and switch feeding state;

It can be adjusted automatically by adding or reducing meals separately according to different situations.

Intelligent adjustment, no manual intervention, optimize labor force, reduce cost and increase efficiency;

Feeding information and dynamic data management of pig herd to provide decision-making guidance for feeding;

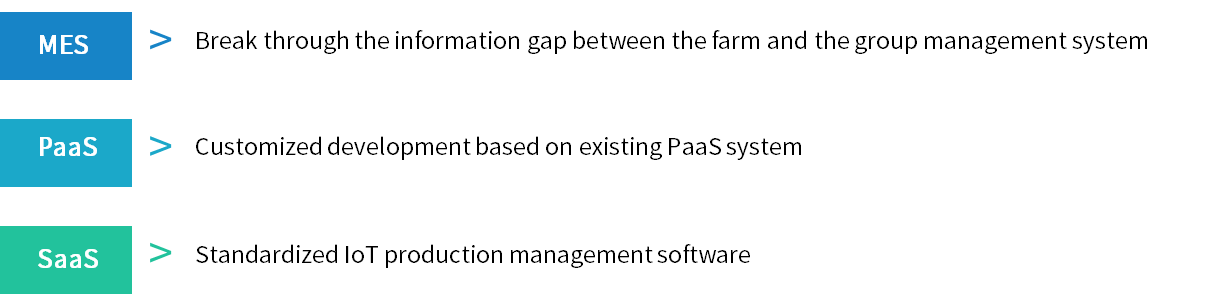

We are committed to building the Only One System platform, combining the traditional AiFarm IoT platform with the ERP system, OA office system, ARS accounts receivable system, and EQ electronic quotation system specially developed for breeding. To solve the problem of information barriers of enterprises, reduce costs and increase efficiency.